Table of Contents

For wood roof systems, builders must follow exterior fire exposure ratings (Class A, B, or C) established through standardized tests such as UL 790 (ASTM E108). The required rating depends on local code, building occupancy, wildfire exposure, and the specific components in the roof assembly.

What is the fire rating of a roof?

A roof fire rating is a classification determined by standardized fire exposure tests that measure flame spread, ember resistance, and the ability of a roof assembly to withstand burning material. Roofs receive Class A, Class B, or Class C ratings depending on their performance.

What is the fire rating of wood?

Wood by itself is generally considered combustible and does not carry a fire rating unless treated, covered, or built as part of a tested assembly. Fire rated wood is usually achieved through pressure treating or by incorporating the wood into a listed roof system.

What are four fire classifications for roof coverings?

The four main fire classifications are Class A, Class B, Class C, and unrated. Class A provides the highest resistance to flame spread and airborne embers, while unrated assemblies fail to meet minimum standards.

What makes wood fire rated?

Wood becomes fire rated through pressure treating, fire retardant coatings, or inclusion within a tested and listed roof assembly where other materials help achieve a Class A, B, or C performance.

According to the Federal Emergency Management Agency, roof assemblies are a critical component of fire resistance, especially in areas exposed to ember-driven wildfires.

Introduction: Why Fire Ratings for Wood Roof Systems Matter for Builders

Fire rated wood roof systems occupy a strange place in modern construction. Builders occasionally encounter them in specialty residential designs, historic restorations, or high-end custom architecture. Yet in states like Florida where strict hurricane codes, fire standards, and moisture concerns dominate construction decisions, wood roof systems are rarely used. When a client or architect requests a fire rated wood roof, builders must understand how these systems are classified, what code pathways exist, and how to avoid failing inspections due to misunderstandings about fire ratings.

This article explains how fire rated wood roof assemblies are tested, what Class A, B, and C ratings mean, the limitations of wood in fire exposure, and how Florida’s code influences design decisions. Builders will walk away with practical code-level knowledge rather than product advocacy so they can manage expectations and ensure compliance.

What Does a Fire Rated Wood Roof System Actually Mean?

A fire rated wood roof refers to a roof assembly that incorporates wood shingles, shakes, or structural wood components while still meeting a Class A, B, or C fire rating under UL 790 (ASTM E108). The key detail for builders is that the fire rating applies to the assembly, not the wood alone. Wood is inherently combustible, so no wood roof covering is naturally Class A unless combined with specific layers such as fire retardant underlayments, cap sheets, or pressure treated products.

Florida builders should note that placing fire rated wood roofing on a structure does not automatically meet local code. The Florida Building Code relies heavily on wind uplift requirements, impact resistance, and underlayment specifications for high velocity hurricane zones that most wood systems cannot satisfy. This makes their use limited to special exceptions or custom homes outside HVHZ areas.

How Are Wood Roof Systems Tested for Fire Ratings?

Fire ratings for wood roof systems are determined through UL 790 or ASTM E108 tests. These tests expose the assembly to flame, radiated heat, and burning embers. Class A systems handle the highest exposure levels. Class B and C provide progressively less resistance. The tests measure flame spread across the roof surface, how long materials resist burning, and whether the assembly allows embers to penetrate.

Builders should remember that fire ratings are assembly-dependent. If a field installation deviates from the tested configuration such as substituting underlayment or skipping a required cap sheet the system no longer matches the listed fire rating. For Florida projects, inspections often fail when a builder attempts to use a fire rated wood shingle but ignores the tested assembly structure behind it.

What Are the Class A, B, and C Ratings for Wood Roof Systems?

Class A assemblies offer the highest fire resistance and provide the strongest protection against flame spread and airborne embers. These are required for many commercial structures and for homes in wildfire-prone zones in states like California or Colorado. Wood can only reach Class A through pressure treating, multilayer assembly design, or special fire resistant roofing barriers.

Class B assemblies offer moderate resistance and are seldom accepted in strict jurisdictions. Class C assemblies provide minimal protection and are typically limited to low-risk applications or very specific architectural contexts. In Florida, Class C wood systems are rarely permitted for new construction, and many jurisdictions reject them outright due to hurricane and fire code restrictions.

Builders handling custom requests must verify whether the local jurisdiction accepts anything below Class A. In most urban or coastal zones, they do not.

Why Florida Rarely Uses Fire Rated Wood Roof Systems

In Florida, the absence of wood roof systems has more to do with wind, impact, and moisture issues than fire. Wood shingles and shakes struggle to pass Miami-Dade approval requirements, resist fungal decay, or maintain structural integrity in humid coastal climates. Fire rating compliance is only one part of the problem. Even if Class A fire performance is achieved, the assembly must also meet ASTM D3161 wind ratings, TAS 100A wind-driven rain tests, and roofing uplift requirements for high velocity hurricane zones.

For this reason, most Florida builders never specify wood roof systems unless working on a unique architectural project, a historic reconstruction in a low-risk county, or a controlled specialty application. Understanding fire ratings becomes essential only when dealing with these exceptions.

What Do Builders Need to Know About UL 790 (ASTM E108) Testing?

UL 790 also known as ASTM E108 is the core test that determines a roof system’s fire classification. It includes the intermittent flame test, spread of flame test, and burning brand test. Wood roof coverings typically struggle with ember resistance unless pressure treated or paired with underlying fire resistant layers.

From a builder’s perspective, two key rules matter. First, only assemblies installed exactly as tested receive the rating. Second, inspectors will verify compliance against the listing, not against the material packaging. This is where builders often get caught during custom installations. A wood shingle labeled as fire retardant is not necessarily part of a Class A assembly.

What Components Influence the Fire Rating of Wood Roof Systems?

A fire rated wood roof system depends on multiple components working together. These include underlayment, fire resistant barriers, ventilation structures, deck thickness, and the specific type of treated wood. Fire retardant wood shingles alone do not create a Class A assembly. The tested assembly may include:

- A specialized fire resistant underlayment

- Mineral surfaced cap sheets

- A double-layer barrier system

- Pressure treated wood shingles or shakes

- Additional sheathing layers

Builders must obtain the official UL listing or code report, not a manufacturer summary. Florida building officials rarely grant approval without complete test documentation.

How Does Fire Rating Interact with Hurricane Code Requirements?

In Florida, wind uplift and water intrusion rules often outweigh fire concerns. A Class A fire rated wood roof system may still be prohibited if it cannot withstand high velocity hurricane forces. Miami-Dade and Broward counties apply the strictest standards. Even outside HVHZ zones, wood roofing may conflict with local wind requirements.

This creates a unique challenge for builders taking on custom high-end projects. Architects may request a fire rated wood aesthetic, but builders must clarify that meeting the fire code does not guarantee meeting the wind or water codes. Builders should present code pathways early in design to avoid redesigns and delays.

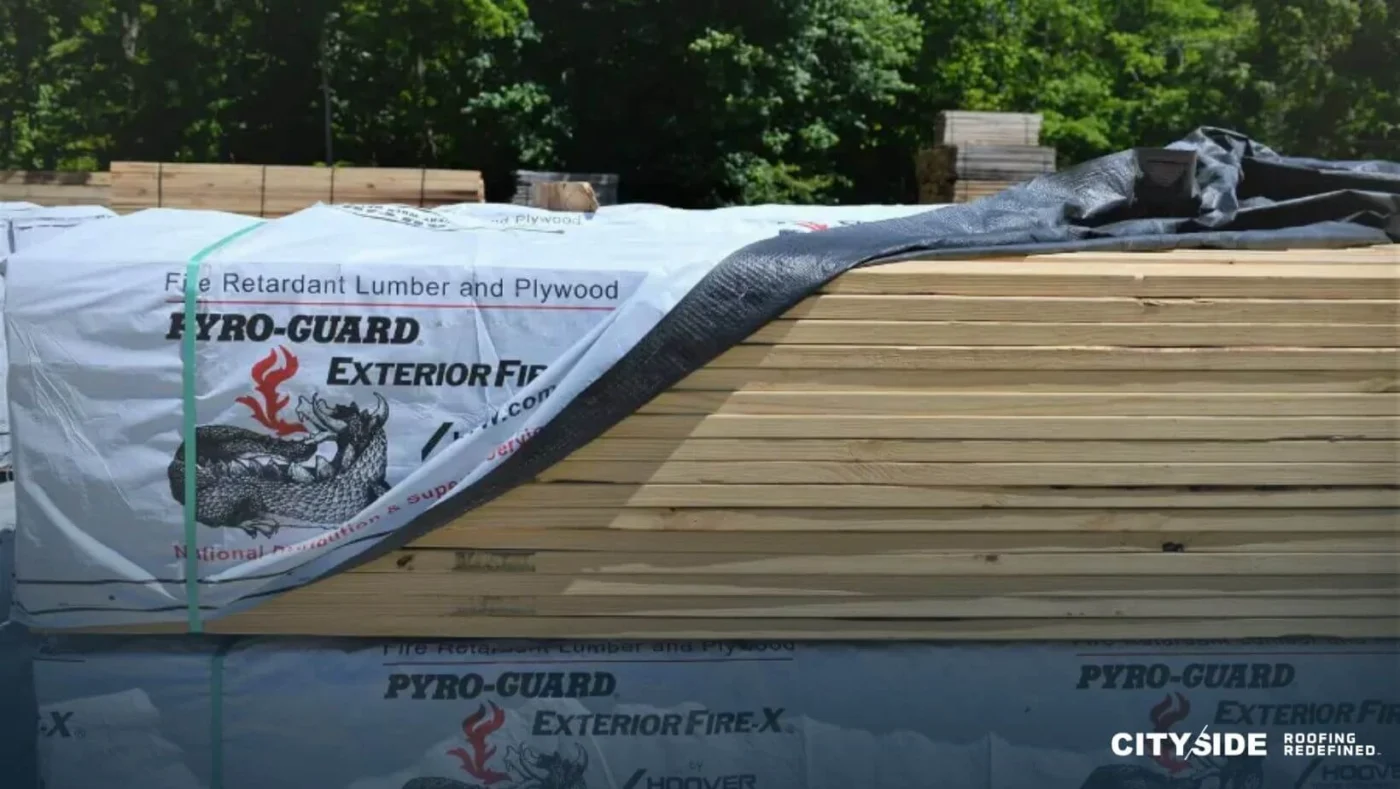

What Do Builders Need to Know About Pressure Treated Fire Rated Wood?

Pressure treated fire resistant wood products are chemically infused to slow ignition and reduce flame spread. These materials are often marketed as Class A shingles or shakes, but the Class A designation usually refers to the assembly, not the shingle alone. Builders must confirm whether the treatment is intended for exterior use. Some fire retardant treatments degrade in humid climates and are not approved for Florida environments.

Additionally, chemical treatments may affect structural fasteners and create corrosion risk if not paired with appropriate hardware. Builders should verify material compatibility, especially in coastal projects.

Are There Special Considerations for Custom Homes and Historic Restorations?

Custom homes are the most likely scenario where a Florida builder may encounter fire rated wood roof requests. Homeowners often want an aesthetic that matches a specific architectural style. In these cases, builders must emphasize code pathways, performance expectations, and limitations related to humidity, wind, and long-term maintenance.

Historic districts may require replication of original materials. In these cases, building officials sometimes allow Class C wood roofing if paired with concealed modern fire resistant layers. Builders must work closely with inspectors and present complete test documentation.

How Should Builders Communicate Fire Rating Requirements to Clients?

Builders often face client confusion about what fire ratings actually mean. Homeowners may assume Class A means noncombustible or maintenance free. It is important to clarify that a fire rated wood roof still behaves as a wood roof and carries ignition risk under extreme conditions. Builders should explain:

- The rating applies only to tested assemblies

- Fire rating does not address wind performance

- Fire rating does not eliminate maintenance requirements

- Florida limitations may restrict or prohibit wood roofing entirely

Clear communication prevents code issues and avoids budget surprises during permitting.

Conclusion: Key Takeaways for Builders

- Wood roof systems achieve fire ratings only through tested assemblies, not individual materials.

- Class A, B, and C ratings are determined by UL 790 or ASTM E108 testing.

- Florida rarely permits wood roof systems due to wind and moisture code limitations.

- Fire rated assemblies must be installed exactly as tested to maintain compliance.

- Pressure treated fire resistant shingles alone do not guarantee a Class A assembly.

- Builders should verify acceptance with local jurisdictions before specifying wood roofing.

- Custom homes and historic projects are the most common scenarios where wood systems appear.

- Early communication with architects and clients prevents code conflicts.

If you need support evaluating roof assemblies or planning code compliant alternatives for custom projects, reach out to CitySide Roofing for builder-focused technical guidance and field-ready expertise.

Related Reading: